There is some indication that the purchase of machinery in the construction industry will soon be at record highs. Just recently, with the advent of Covid-19, sales have been extremely low for quite some time. Due to the virus, people have been out of work or at least staying at home, which can minimize the need for any type of machinery. Even if they had machinery that needed to be replaced, they held off due to a lack of sales that would provide them with the money to make these investments. There are also other reasons why machinery demand has been low, and why in 2021 it may see record highs for the following reasons.

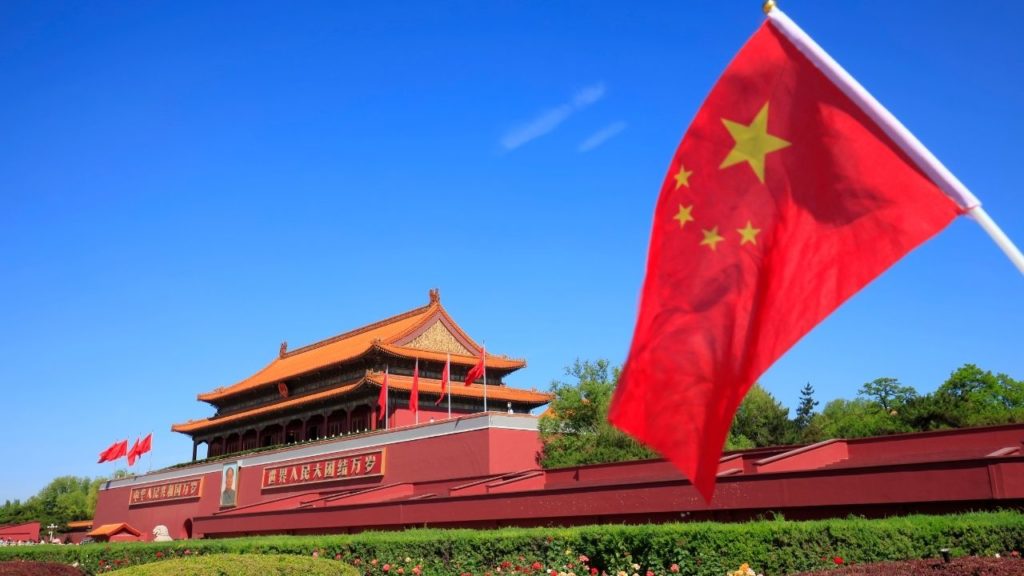

Growth In China

Covid-19 is thought to have originated in China. At the very least, it was in this area of the world that production began to slow in all industries. With so many people sick, and also quarantine, the economy of China began to slump first. As a result of this, competing factors began to happen at the same time. First of all, you had lower production rates for all businesses, leading to fewer products being sold and less revenue being generated. Conversely, we also had an abundance of machinery that was just sitting there. This is why, in 2021, there is likely to be a major movement of this machinery to recoup lost profits. China was the first to slow down, but now the economy is speeding up, which will lead to a higher volume in sales.

An Increase In Global Sales

Subsequent to the movements of the Chinese economy, we began to see other economies begin to recover. As they began to put more people back to work, more machinery was needed, thus raising the demand for Machinery Insurance as well. In the same way that China began to sell more products, other countries began to do the same. Part of that marketing of products involved the use of machinery that was needed by businesses worldwide to recover from the losses in the prior year. This takes us to the United States, where the pandemic was the worst, and where they are now beginning to recover. That is why the forecast is looking promising for machinery demand as America tends to be the largest consumer of machinery used by businesses.

Will This Trend Continue Beyond 2021?

There is some speculation as to whether this upward trend for the demand for machinery will continue. This, again, has to do with the virus. Many outbreaks began to intermittently occur in places all over the world. This caused additional shutdowns, for months at a time, thus causing problems with the demand for machinery. Fortunately, these outbreaks were short-lived, allowing businesses to recover at a much faster pace. With the advents of the vaccine, which many people have taken, this will likely lead to fewer outbreaks in the future for the countries that have access to the vaccine.

What Type Of Machinery Is In Demand In The Construction Industry?

More specifically, it is the machinery in the construction industry that has come into question. Of course, the demand for this machinery, like all others, will ebb and flow depending upon outbreaks of the virus. The construction industry, in particular, can be affected by many different factors. It’s not just the virus that is causing interruptions in machinery demand. For example, unexpectedly, the rise in prices for existing homes has gone up. Despite this, the purchase of homes has been on the increase all throughout 2021. People are buying homes, sometimes outbidding others of the same piece of property, even though fewer people are working now than in the last several decades. Regardless of why this is happening, new construction projects may not be at the forefront, thus minimizing the need for heavy machinery for new projects. As this continues, constant monitoring is recommended, for businesses that produce machinery used by construction workers.

At the present time, the cost of lumber has begun to rise again. This is far down from the unbelievably high cost of lumber in may of 2021. Since the end of July, prices have remained relatively stable, allowing construction projects to begin to resume. However, the price of lumber is spiking right now, which could inhibit the need for machinery for projects that may not happen at all. It is always good to look at multiple aspects of the construction industry when determining the need for machinery. Right now, the outlook looks promising due to the lower cost of lumber and the demand for new housing.